1. Torque Wrenches: Reliability, best quality, low weight, high strength torque wrenches are the most versatile torque wrenches in industry

1.1 TWHC High Cycle Torque Wrench

Features

- Designed for high cycle life: 2 to 3x more than existing technology

- Increased reliability: simple drive assembly means less downtime

- Corrosion resistant material used for use in harsh environments

- Compact nose radius allows the tool to fit in tighter, hard-to-reach spaces

- Low weight, high strength design

- Fast operation, long stroke and optimum flow

- Multi-direction high flow swivel manifold

- Push button square drive reversal and reaction arm positioning

- Push-button release of square drive & reaction arm for all models except TWHC50

More information

https://www.spxflow.com/bolting-systems/products/torque-wrenches

1.2 TWSD: Square Drive Torque Wrench: Light weight, high strength tool features superior torsional strength, fast operation cycle, fine tooth pawl and floating piston design.

Features

- Low weight, high strength design

- Superior torsional strength

- Fast operation cycle, Fine tooth ratchet

- Floating piston design

- Swivel manifold internal relief valve prevents retract side over-pressurization

- Rigid steel body construction, Compact frame size

- Reaction and drive accessories available

- Push button reversal of square drive

- Corrosion resistant finish

- 360° reaction arm

- Push to lock reaction arms

- Multi-axis high flow swivel manifold

- Consistently accurate torque output

More information

https://www.spxflow.com/bolting-systems/products/torque-wrenches

1.3 TWLC: Low Clearance Torque Wrench: The lightweight, heavy-duty tool features low height and tight nose radius.

Features

- Low Weight, High Strength Design

- Superior Torsional Strength

- Fast Operation Cycle

- Floating Piston Design

- Auto-Connect Drive Piston

- Compact Frame Size

- Rigid Steel Body Construction

- Internal swivel manifold Relief

- Built-in Reaction Pad, Small Nose Radius

- Corrosion Resistant Finish

- Multi-Axis High Flow Swivel Manifold

- Consistent Torque Output

- Powerthon™ Lifetime Warranty

More information

https://www.spxflow.com/bolting-systems/products/torque-wrenches

1.4 TWSL Slimline Torque Wrench: They are engineered to meet the demand for a tighter fitting wrench in various markets.

Features

- Dynamic engineering modeling (FEA) optimized tool design to extend life and durability

- The SlimLine links use the same quick change Drive Body as the existing TWLC links

- Small nose radius, fits all standard API and ANSI flanges

- Rigid steel body construction with corrosion resistant plating

- Fully enclosed drive mechanism for operator safety

- Swivel manifold has an internal relief valve to prevent retract side overpressurization

- Multi-Swivel technology for free positioning of tool and hoses

More information

https://www.spxflow.com/bolting-systems/products/torque-wrenches

2. Tensioners: Economy range of bolt tensioner reduces operator fatigue, saving time and improving safety and productivity offer low cost tensioning solutions

2.1 SRT: Top Side Tensioner: Spring Return, features unique quick release bridge adaptation, piston stroke indication and piston over stroke prevention.

Features

- Piston overstroke prevention, Piston stroke indication

- Compatible with MRT Tensioner range

- Unique quick release bridge adaptation

- Piston/cylinder misalignment compensation

- Bolt coverage from 3/4″ to 4″ (20 – 115 mm) with just 8 tools

- Designed to fit BS1560/ANSI B16.5/API flanges

- Fully enclosed load cell design eliminates entry of debris into piston retraction mechanism

- Piston over-stroke eliminator to prevent over stroking and blowing a seal

- Twin hydraulic couplings for multiple tool connections

- Requires stud to protrude above nut by 1 x bolt diameter

- Max tool pressure: 21,750 psi (1,500 bar)

- Bolt protrusion above nut: 1 x bolt diameter (minimum)

More information

https://www.spxflow.com/bolting-systems/products/tensioners

2.2 MRT: Bolt Tensioner Manual Return: Manual Return, incorperates our unique quick-release bridge adaptation, a range of adapter kits provide maximum flexibility.

Features

- Our economy range of bolt tensioners offer low-cost tensioning solutions.

- Incorporating our unique quick-release bridge adaptation, a range of adapter kits provide maximum flexibility.

- Piston stroke limit indication

- Piston/cylinder misalignment compensation

- Bolt coverage from 1″ to 3-1/2″ with just 6 tools

- Designed to fit BS1560/ANSI B16.5/API flanges

- Unique quick-release bridge adaptation

- Application specific tooling available. Contact factory for details.

- Piston stroke: 15mm (excluding MRT1 – 10mm)

- Max tool pressure: 21,750 psi (1,500 bar)

- Bolt protrusion above nut: 1 x bolt diameter

- To make a complete MRT Tensioner, choose an Adapter Kit and a Load Cell.

- Semi-compatible with SRT tensioners. Only compatible with SRT Bridges; NOT puller sleeves. SRT Puller Sleeves cannot be used with MRT Load Cell.

More information

https://www.spxflow.com/bolting-systems/products/tensioners

2.3 WDD: Wind Tensioner Up Tower: Uptower & Uptower with space contstraints

Features

Quality Means Lower Life–Cycle Costs:

- Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts

- Fully enclosed load cell eliminates debris in piston retraction mechanism

- Auto-Engaging Geared Nut Rotator and Self-energizing, long life seals

Enhanced Usability:

- Piston stroke limit indication and Automatic piston retraction mechanism

- High pressure swivel coupling (swivel is optional on WSS & WSL)

- 19,580 psi (1,350 bar maximum operating pressure)

Designed with Safety in Mind:

- Overstroke prevention for safe operation

- Anti-slip grip surface and Tool lifting-strap as standard

WDD UP TOWER WIND TENSIONERS

- Robust Gearbox Drive

- Auto-Engaging Geared Nut Rotator

- Small diameter, high load 2-Stage hydraulic load cell

- Fast application using 1/2″ drive

- Max Pressure: 19,580 psi (1,350 bar)

More information

https://www.spxflow.com/bolting-systems/products/tensioners

WER WIND TENSIONERS

2.4 WSD: Wind Tensioner Compact Tower: For Foundation bolts, compact tower with space contstraints

Feature

Quality Means Lower Life–Cycle Costs:

- Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts

- Fully enclosed load cell eliminates debris in piston retraction mechanism

- Auto-Engaging Geared Nut Rotator and Self-energizing, long life seals

Enhanced Usability:

- Piston stroke limit indication and Automatic piston retraction mechanism

- High pressure swivel coupling (swivel is optional on WSS & WSL)

- 19,580 psi (1,350 bar maximum operating pressure)

Designed with Safety in Mind:

- Overstroke prevention for safe operation

- Anti-slip grip surface and Tool lifting-strap as standard

WSD COMPACT TOWER WIND TENSIONERS

- Robust Gearbox Drive

- Auto-Engaging Geared Nut Rotator

- Low height hydraulic load cell and Fast application using 1/2″ drive

- Maximum operating pressure 19,580 psi (1350 bar)

More information

https://www.spxflow.com/bolting-systems/products/tensioners

2.5 WSS & WSL: Wind Tensioner Foundation: For Foundation bolts with space contstraints

Features

Quality Means Lower Life–Cycle Costs:

- Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts

- Fully enclosed load cell eliminates debris in piston retraction mechanism

- Auto-Engaging Geared Nut Rotator

- Self-energizing, long life seals

Enhanced Usability:

- Piston stroke limit indication

- High pressure swivel coupling (swivel is optional on WSS & WSL)

- 19,580 psi (1,350 bar maximum operating pressure)

- Automatic piston retraction mechanism

Designed with Safety in Mind:

- Overstroke prevention for safe operation

- Anti-slip grip surface

- Tool lifting-strap as standard

WSS & WSL FOUNDATION WIND TENSIONERS

- Suitable for ISO Metric threaded and all-thread bars

- Geared or Manual Nut Rotator

- Maximum operating pressure 19,580 psi (1350 bar)

- Uses standard system ‘nut’ for reaction

- Contact factor for optional swivel coupling

More information

https://www.spxflow.com/bolting-systems/products/tensioners

2.6 SST: Subsea Stud Tensioner: Features quick reaction nut, visible piston stroke indication and anti-slip cylinder surface for improved handling.

Features:

- Visible piston stroke indication

- Positive ‘over-stroke’ stop to prevent piston expulsion/seal damage.

- Piston/cylinder misalignment compensation

- Anti-slip cylinder surface for improved handling

- Low friction seals

- Anti-corrosion coating

- Bolt coverage from 3/4″ to 4″ (M20 to M100)

- Designed to fit BS1560/ANSI B16.5/API flanges, as well as most compact flange designs

- Piston stroke: 30mm except for SST1 – 20mm

- Max tool pressure: 21,750 psi (1,500 bar)

- Bolt protrusion above nut: refer to chart (specification) for stud protrusion requirements

More information

https://www.spxflow.com/bolting-systems/products/tensioners

2.7 SBT: Segmented Bolt Tensioner: Combined with our quick reaction nut provides the fastest and most efficient bolt tensioning solution ever.

Features

Quick Reaction Nut, solid nut or puller sleeve versions

- Visible piston stroke indication

- Piston / cylinder mis-alignment compensation

- Available in Subsea and Topsides versions

- Designed to fit most flange configurations

More information

https://www.spxflow.com/bolting-systems/products/tensioners

3. Pumps: Air and Electric Powered Torque Pumps

3.1 PE45 Infinity Series Electric Pump: The SPX FLOW PE45 is an Infinite Stage Electric Pump which increases productivity on the job by providing continuous pressure for up to two times the speed of typical 2-stage pumps.

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122°F (50°C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Light Weight: 71 lb (32.2 kg) [without oil]

- Removable control pendant (15 ft / 5 m)

- Removable (4″) 100 mm, calibration-capable gauge

- Universal Motor for reduced voltage applications (up to -20% nominal voltage)

- 4 tool manifold available powers up to 4 tools from a single pump (not for lifting applications)

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Fixed 1,500 psi (103 bar) retract relief valve pressure

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.2 PA60A Infinity Series Air Pump: Up to 200% faster than 2-stage pumps and up to 4 torque wrench tools on 1 pump (10,000 PSI (700 BAR) INFINITY SERIES (ISP) AIR PUMP)

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 50°C (122°F) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Light weight and portable: 77 lb (34.9 kg) [without oil] PA60APF5FP

- Light weight and portable: 88 lb (40.1 kg) [without oil] PA60APF5FMPR

- Removable control pendant (25 ft / 7.6 m)

- Removable 4″ (100 mm), calibration-capable gauge

- CE

- ATEX Ex II 2 GDc T4

- 4 port manifold available to power up to 4 tools from a single pump (not for lifting applications)

- Fewer parts for lower service cost

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Fixed 1,500 psi (103 bar) retract relief valve pressure

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.3 PE39 Compact Electric Torque Wrench Pump: Newly designed Compact Pump incorporates new proven pump design for reliable operation in rugged torque wrench applications (10,000 PSI (700 BAR) COMPACT ELECTRIC TORQUE WRENCH PUMP).

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122˚F (50˚C) ambient

- Proven design = proven reliability

Enhanced Usability:

- Light weight and portable: 39 lb (17.7 kg)

- Removable control pendant (15 ft / 5 m cord length)

- Removable 4″ (100 mm) calibration-capable gauge

- Universal Motor for reduced voltage applications (up to -20% nominal voltage)

- Vertical or horizontal operation

- Easy install cooling fan as option

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Fixed 1,500 psi (103 bar) retract relief valve pressure

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.4 PE55TWP Classic Series Electric Hydraulic Pump: 704 cu. in./min. Vanguard® Series Torque Wrench Pump (10,000 PSI (700 BAR) CLASSIC SERIES ELECTRIC HYDRAULIC PUMP).

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122°F (50°C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Two Speed High Performance pump

- Retract side internal relief valve protects tool

- Hand remote

- Four-tool manifold (-4 models only) allow use of up to four tools simultaneously

- 4″ calibration capable gauge

- Use with single or double acting tools

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- 1,500 psi (103 bar) pressure retract relief valve

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.5 X1E1–PT Legacy Series Electric Hydraulic Pump: 10,000 PSI (700 BAR) CLASSIC SERIES ELECTRIC HYDRAULIC PUMP

Feature

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122°F (50°C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Power Team, two-speed high performance, PE55 base pump

- Retract side internal relief valve protects tool

- 4-way 2-position solenoid valve standard

- Use with single or double acting tools, not for lifting applications

- Hand remote standard

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Fixed 1,500 psi (103 bar) pressure retract relief valve

3.6 RWP55–BS Classic Series Air Hydraulic Pump: 10,000 PSI (700 BAR) CLASSIC SERIES AIR HYDRAULIC PUMP

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122°F (50°C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Powerful 3 hp motor starts under load

- Retract side internal relief valve protects tool

- Use with single or double acting tools. Not for lifting applications

- 4″ calibration capable gauge

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Has a retract port pressure selector 10,000 psi (1,500)

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.7 X1A1–PT Legacy Series Air Hydraulic Pump: 10,000 PSI (700 BAR) CLASSIC SERIES AIR HYDRAULIC PUMP

Feature

Quality means Lower Life–Cycle Costs:

Over 100,000 cycles

Continuous duty up to 122°F (50°C) ambient

Proven design = Proven reliability

Enhanced Usability:

- Power Team, two-speed high performance, PA55 base pump

- Retract side internal relief valve protects tool

- 4-way 2-position air pilot valve standard

- Use with single or double acting tools. Not for lifting applications.

- Hand remote standard

Designed with Safety in Mind:

- Easily adjusted pressure regulator (relief) valve

- Fixed 1,500 psi (103 bar) pressure retract relief valve

3.8 PE8 High Pressure Electric Pump: 21,750 PSI (1,500 BAR) HIGH PRESSURE ELECTRIC PUMP

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122˚F (50˚C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Light Weight and portable: 45.5 lb (20.6 kg) [without oil]

- Quick Release, removable control pendant (15 ft / 5 m)

- Removable 4″ (100 mm), calibration-capable, gauge

- Universal Motor for reduced voltage applications (up to -20% nominal voltage)

- SPX Tensioners are designed to daisy-chain together so multiple tools can run off one pump

- Compact design fits into tight spaces

Designed with Safety in Mind: Easily adjusted pressure regulator (relief) valve

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.9 HPUTP–1 Standard Flow Tensioner Pump: HPUTP-1: 21,750 PSI / 1,500 bar

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 122°F (50°C) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Calibrated 6″ (150mm) Pressure Gauge

- Dual oil outlets with quick-connect, no spill couplings

- Pneumatic Filter/Regulator/Lubricator included

- Stainless Steel carry frame

Designed with Safety in Mind:

- Easily adjusted pressure regulator valve

- Air pressure safety relief valve

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.10 HPUTP–2 High Flow & Subsea Tensioner Pump: 1,500 BAR (21,750 PSI) SUBSEA & LARGE TENSIONER APPLICATIONS

Features

Quality means Lower Life–Cycle Costs:

- Over 100,000 cycles

- Continuous duty up to 50°C (122°F) ambient

- Proven design = Proven reliability

Enhanced Usability:

- Calibrated 150mm (6″) Pressure Gauge

- Dual oil outlets with quick-connect, no spill couplings

- Pneumatic Filter/Regulator/Lubricator included

- Stainless Steel carry frame

Designed with Safety in Mind:

- Easily adjusted pressure regulator valve

- Air pressure safety relief valve

More information

https://www.spxflow.com/bolting-systems/products/pumps

3.11 HPUHP150001 High Pressure Hand Pump: 21,750 PSI / 1,500 Bar

Features

TWO STAGE, HIGH PRESSURE HAND PUMP

- Two-speed reduces handle strokes so you work faster and easier.

- Built-in, protected pressure gauge.

- Ergonomic design for minimal handle effort.

- Lightweight aluminum reservoir.

- Easily accessible refill port.

- Needle valve allows full control when releasing tension.

More information

https://www.spxflow.com/bolting-systems/products/pumps

4. Nut Splitters: Best solutions of removing corroded, and toughest fused or rusted nuts

4.1 ENS: Nut Splitter: Our Hydraulic nut splitter offers a reliable and effective solution to the removal of seized and corroded nuts.

Features

- Triple edge replaceable cutting blade

- Blade positioning scale to eliminate bolt damage

- Cutting depth fixed – Nut size adjustable via rotating cylinder!

- Size range from 3/4″ to 3-1/2″ bolt diameters

- Designed to fit ANSI, ASME B.16.5 flanges

- Twin line hydraulic version available for subsea use

- Versatile, reliable and trouble-free operations

- Operates off a standard 10,000 psi (700 bar) pump unit

- Built-in safety relief valve to protect tool & operator

- Double acting (subsea) version comes standard with 700 bar, 1/4″ NPT, Push to Connect (PTC) couplers.

- To use with top side pumps, change out couplers to 700 bar, 1/4″ NPT, Screw-to-connect style.

More information

https://www.spxflow.com/bolting-systems/products/tools

4.2 HNS: 15 – 25 Ton Nut Splitter: Hydraulic Nut Splitter will deliver enough force to split the toughest fused or rusted-on grade 2H nuts.

Features

- Specially designed “tool steel” cutter blade penetrates the nut to the precise point where it cracks, stopping short of the bolt threads

- Nut splitter features a dramatically improved cutter blade with an 800% greater resistance to chipping and breaking over previous models

- All models feature a rugged one-piece cutting frame coupled to a heavy-duty hydraulic cylinder

More information

https://www.spxflow.com/bolting-systems/products/tools

5. Flange Spreader

This unit is ideal for pipe and flange repair. It can also be used for removing elbows, gasket and metal seal replacement on couplers, heavy equipment maintenance, and many other tasks. The spreader is capable of developing up to 15 metric tons of force, is lightweight, and easy to use due to

its ergonomic design

https://www.spxflow.com/bolting-systems/products/tools

6. Software

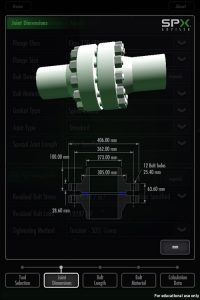

6.1 Advisor

The adviser software considers many years of bolt working experience, where data has been channeled into a single computer software program. Bolt tightening data, procedures and recommendations for standard flanged joints, makes adviser an invaluable tool to any industry. The Adviser software package includes:

• Tightening data for BS1560, MSS SP44, API 6A and 17D flanged joints.

• Encompasses standard flanges, wafer check valves, spade and spacers, and

swivel flange assemblies.

• Torque data and tensioning tool pressures for both Subsea and Topsides

applications.

• Bolt extension calculations.

• Tightening procedures and Torque sequences.

• Joint specific recommendations for improved integrity.

• Large database of bolt materials.

• Large database of bolt lubricants.

• Dimensional data of flanges.

• Recommended bolt lengths.

• Simple user interface with ‘Windows’ look and feel

https://www.spxflow.com/bolting-systems/products/software

6.2 FLANGE PRO

Our newest innovation is the introduction of FLANGE PRO , a software solution offering the ultimate secure, safe and traceable flange management system. The implications of leakage from connections in process pipework can be extremely serious, and with many thousands of connections on site, from flanges to valves to small bore connections, maintaining integrity and 100% containment is an extremely high priority. FLANGE PRO has been designed to improve safety, reduce risk and save money. Protecting assets, protecting people and the environment.

A global, collaborative cloud-based system, FLANGE PRO provides secure access to any project, on demand, anywhere in the world.

FLANGE PRO captures and records all integrity activities on all safety critical plant and equipment. Providing access through a simple intuitive user interface and gives you the information you need, when you need it. Whether in planning, construction, operations, maintenance or working on turnaround activities, FLANGE PRO is the integrity solution for all flange management situations.

Flange Management Systems can help address elements of SEMS, SEMS II, and RP 75, such as: •

Maintaining key information on flanged joints, leak testing, and controlled bolting bolt load calculations and methods. • •

Documentation of operating procedures for controlled bolting processes. Help maintain mechanical integrity of piping assets.

Flange Management Systems can help address KP4 requirements: •

Help track flange records for aging assets and maintain a documented record of their condition.

Furthermore, Flange Management Systems provides a system to help manage hydrocarbon-containing equipment from experiencing a hydrocarbon release.

The Deepwater Horizon accident resulted in the loss of eleven lives and the overall cost was several billion dollars. The Piper Alpha accident cost the loss of 167 lives and changed the face of the North Sea Oil & Gas industry entirely.

A high consequence event that occurred in a California refinery which resulted when a 4″ 300# gasket failed due to improper tightening. The refinery reported that consequential damages due to production loss, fines, and rework were in excess of $500M*. (Source: 2014 AFPM

Reliability & Maintenance Conference)

https://www.spxflow.com/bolting-systems/products/software